Continuous process improvement is a powerful concept that has gained increasing traction in digital business environments. By consistently refining processes, businesses can maximize efficiency, adapt to change, and remain competitive in a fast-evolving digital landscape.

What is Continuous Process Improvement?

Continuous process improvement (CPI) refers to the ongoing effort to enhance business processes to achieve better performance, efficiency, and outcomes. Unlike one-time optimization projects, CPI is a long-term approach focused on incremental improvements. This philosophy is rooted in constant evaluation, innovation, and collaboration to identify bottlenecks or inefficiencies.

When applied to digital business processes, CPI examines workflows within tools such as CRMs, ERPs, and other software systems. The digital nature of modern businesses makes such analysis easier, with data collection and monitoring enabling real-time insights into process performance.

Benefits of Continuous Process Improvement

Adopting CPI in a digital context provides numerous benefits, including:

- Enhanced efficiency – Streamlining repetitive and complex workflows ensures less wasted time and effort.

- Cost savings – Eliminating inefficiencies can significantly reduce operational expenses.

- Improved customer satisfaction – Faster processes lead to quicker response times and improved experiences.

- Data-driven decision-making – By leveraging analytics tools, companies can base process improvements on hard data rather than assumptions.

- Adaptability – Regular refinements help businesses stay flexible, responding effectively to market changes or new technology.

Key Methodologies in Continuous Process Improvement

Several established methodologies support CPI initiatives. Adopting the right approach depends on the organization’s goals and digital processes. Some of these methodologies include:

- Kaizen – Originating from Japan, Kaizen focuses on small, incremental improvements implemented over time with the involvement of all team members.

- Six sigma – This data-driven methodology seeks to minimize defects by identifying and eliminating variances in a process.

- Lean – Lean practices aim to streamline workflows by eliminating non-value-adding activities and reducing waste.

- Agile – Common in software development, Agile emphasizes iterative improvements and flexibility to meet changing requirements.

- PDCA cycle – The “Plan-Do-Check-Act” framework guides teams through continuous testing and refinement so processes evolve sustainably.

Best Practices for Continuous Process Improvement

To fully leverage CPI in a digital business, organizations must integrate technology effectively. Here are some best practices for digital process optimization:

- Process monitoring tools. Leverage workflow management software, robotic process automation (RPA), and process mining tools to gain a clear view of operations. These tools provide real-time monitoring and detailed reports, making inefficiencies easier to spot.

- Data utilization. Collect, visualize, and analyze process data to understand patterns and trends in performance. This insight helps in prioritizing improvement areas.

- Employee engagement. Include teams who work on these processes daily. Their input provides invaluable insight into on-ground challenges and potential solutions.

- Automation. Use automation to handle repetitive tasks, allowing employees to focus on problem-solving and creative work.

- Feedback loops. Create mechanisms for regular employee and customer feedback to capture new opportunities for improvement.

Future Trends in Continuous Process Improvement

The digital evolution of CPI continues to unlock possibilities. Here are some trends reshaping how businesses approach it in the coming years:

1. Business Orchestration and Automation Technology (BOAT)

Taking automation to the next level, BOAT integrates technologies like AI, RPA, and machine learning for end-to-end process automation.

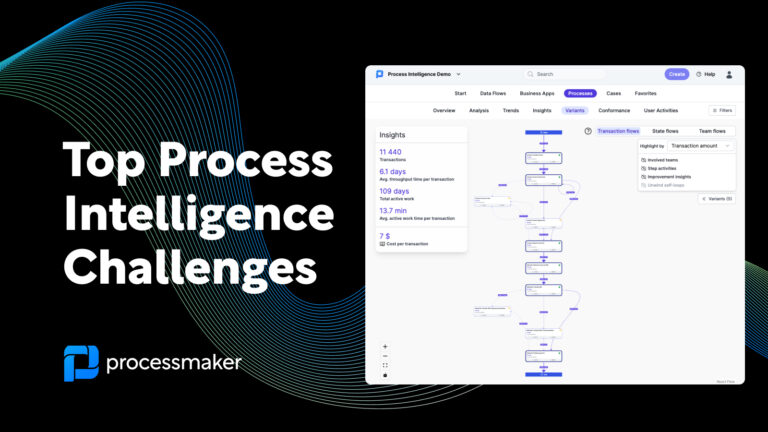

2. Process intelligence (PI)

PI helps companies continuously monitor processes and evaluate the implemented automation initiatives. This helps organizations stay on top of their workflows and implement automation in the most critical places.

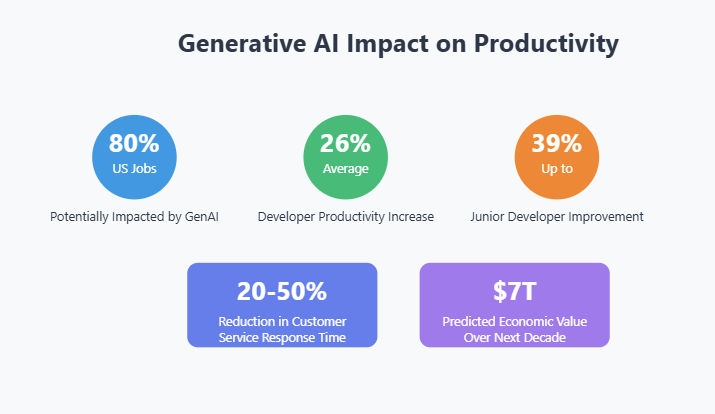

3. Artificial Intelligence and Machine Learning

AI-powered analytics tools will offer predictive insights, identifying issues before they occur and presenting optimization strategies.

4. Real-time process optimization

With IoT and big data, companies can optimize processes dynamically. For example, supply chain processes can adjust automatically to disruptions.

5. Focus on sustainability

CPI efforts will increasingly prioritize eco-friendly processes, reducing waste and energy consumption while meeting ESG compliance goals.

Building a Culture of Continuous Improvement

Continuous process improvement is more than a series of actions—it’s a mindset. For digital businesses, this mindset needs to be embedded into the organizational culture. Leaders must champion the use of advanced tools, empower employees to contribute ideas and maintain flexibility in adapting to new demands.

By fostering a culture of continuous improvement, businesses not only enhance operational performance but also ensure resilience in a rapidly changing world. Whether you’re just starting your CPI journey or looking to refine it further, focusing on sustainable, incremental improvements will position your organization for long-term success.

CPI isn’t just a strategy—it’s a commitment to excellence, innovation, and growth in every facet of your digital operations.