As businesses become more digitalized and complex, the ability to streamline operations and improve efficiencies is a secret superpower. One effective way to achieve this is through business process improvement as a strategic approach aimed at identifying and addressing inefficiencies within existing processes. This involves examining current business processes, identifying areas for improvement, and implementing changes to enhance efficiency.

We’ll go through how to create a process improvement plan in 4 simple steps, but first, let’s cover some foundations of business process management.

Understanding process improvement

Process improvement is a systematic approach to identifying and addressing inefficiencies within business processes. It involves analyzing existing processes, pinpointing areas for enhancement, and implementing changes to boost efficiency, productivity, and customer satisfaction. Unlike one-time projects, process improvement is an ongoing effort that requires continuous monitoring and evaluation to ensure that processes remain effective and efficient. By regularly assessing and refining business processes, organizations can adapt to changing market conditions, meet customer expectations, and maintain a competitive edge.

Benefits of a well-implemented continuous improvement plan

Process improvement plans can yield many benefits, including cost savings, improved productivity, better quality control, enhanced customer satisfaction, and increased profitability. Streamlined processes can lead to more efficient operations and improved resource utilization. They also allow businesses to remain competitive by facilitating innovation and continuous improvement.

Who should be on a process improvement team?

Process improvement is a team sport. Planning and executing structured changes within an organization through process improvement initiatives requires an effective and collaborative team consisting of different roles:

- a project management team led by a process excellence or improvement project manager,

- executive sponsors from the business unit leadership or company management,

- subject matter experts and process owners who are the experts in the work being done.

Process improvement planning requires cross-functional communication and planning skills, so keep in mind also the right mix of skills and experience to coordinate and execute projects successfully across business operations.

Choosing a process improvement methodology

Selecting the right process improvement methodology is crucial for the success of your improvement initiatives. Each methodology has its own strengths and is suited to different types of challenges. Here are some popular methodologies to consider:

- Lean: Focuses on eliminating waste and maximizing value for customers. Lean principles help streamline processes, reduce costs, and improve overall efficiency.

- Six Sigma: Aims to reduce defects and variations in processes. By using data-driven techniques, Six Sigma helps improve quality and consistency.

- Kaizen: Emphasizes continuous improvement and employee involvement. Kaizen encourages small, incremental changes that collectively lead to significant improvements.

- Total Quality Management (TQM): Focuses on customer satisfaction and continuous improvement. TQM involves all employees in the process of improving quality and performance.

- Theory of Constraints: Identifies and addresses bottlenecks in processes. By focusing on the most critical constraints, this methodology helps optimize the entire process flow.

When choosing a methodology, consider the specific needs and goals of your organization, as well as the level of employee involvement and training required. The right methodology will align with your business strategy and support your continuous improvement efforts.

Identifying process improvement opportunities

Identifying process improvement opportunities requires a thorough analysis of existing processes. Some common signs that a process needs improvement include inefficiencies and waste, high error rates or defects, long cycle times or delays, low customer satisfaction, and inadequate training or resources.

To uncover these opportunities, use tools such as process mapping, root cause analysis, and customer feedback. Involving employees in the identification process is crucial, as they have firsthand knowledge of the processes and can provide valuable insights. This collaborative approach not only helps in identifying improvement areas but also fosters a sense of ownership and engagement among employees.

What a process improvement plan should include

A well-rounded process improvement plan should encompass several key elements.

A SMART process challenge

Firstly, the process improvement objective is vital. This could be a range of goals, from reducing costs to increasing efficiency or improving customer satisfaction. A clear direction ensures all process improvement efforts have a defined purpose.

A good objective can be described in a process challenge statement. This is ideally described in the form of a smart goal, that is (s) specific, (m) measurable, (a) attainable, (r) relevant, and (t) time-bound. For example, it could be “To improve our customer NPS, we plan to reduce the throughput time of our new customer onboarding process by 30% before the end of next quarter.”

Business process improvement discovery

Next comes process discovery. It’s crucial to have a thorough understanding of the as-is state of current processes. By meticulously examining the existing operations, you can highlight inefficiencies, redundancies, or bottlenecks that should be rectified.

There are different ways you can diagnose and discover existing process health, whether it is through task mining or process mining software, or through a process discovery workshop or analysis. Whichever method you choose, keep in mind these process discovery best practices.

Process map

The third key element of process improvement plans is process mapping. A process map is a visual representation of the process, created using flowcharts or similar diagrammatic tools, and assists in identifying root causes of inefficiencies. It lays out the process step-by-step, making it easier to spot issues and devise solutions.

Process mapping allows you to document and communicate the health of existing processes and process performance. They can also be used to document inefficient processes and increase resource efficiency by re-designing current process flows.

Implementation and communication strategy

After this comes the implementation strategy and communication plan, where the necessary changes are defined and communicated to key stakeholders. Depending on the specific needs of the business, these can range from minor adjustments to complete overhauls.

An effective communication strategy is paramount to ensure that all stakeholders are in the loop. Everyone involved should be aware of the upcoming changes, understand why they’re being implemented, and be prepared for their roles in the transition. If the improvements require employees to learn new skills or tools, training programs need to be planned and executed.

Process measurement and standardization

Finally, performance measurement should be set up to assess the success of the process improvements. Regular measurement of these key performance indicators (KPIs) helps determine the effectiveness of the changes and guide necessary adjustments. The process improvement journey doesn’t end when the changes are implemented; the improved process should be reviewed periodically for further potential improvements.

With effective measurement in place, you can ensure process standardization. This allows you to confirm that different teams and stakeholders are all conforming to the agreed process improvement plan and process maps.

Remember, the ultimate goal of a process improvement plan is to enhance business performance by refining crucial processes. It’s not a one-time project but should foster a culture of continuous enhancement.

Step-by-step guide to creating a process improvement plan

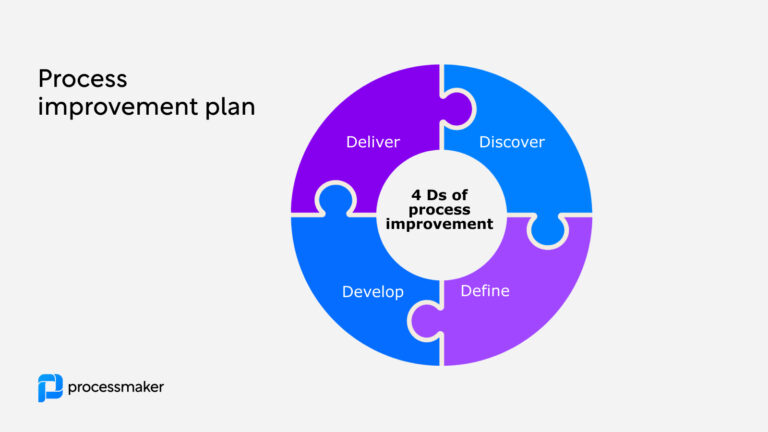

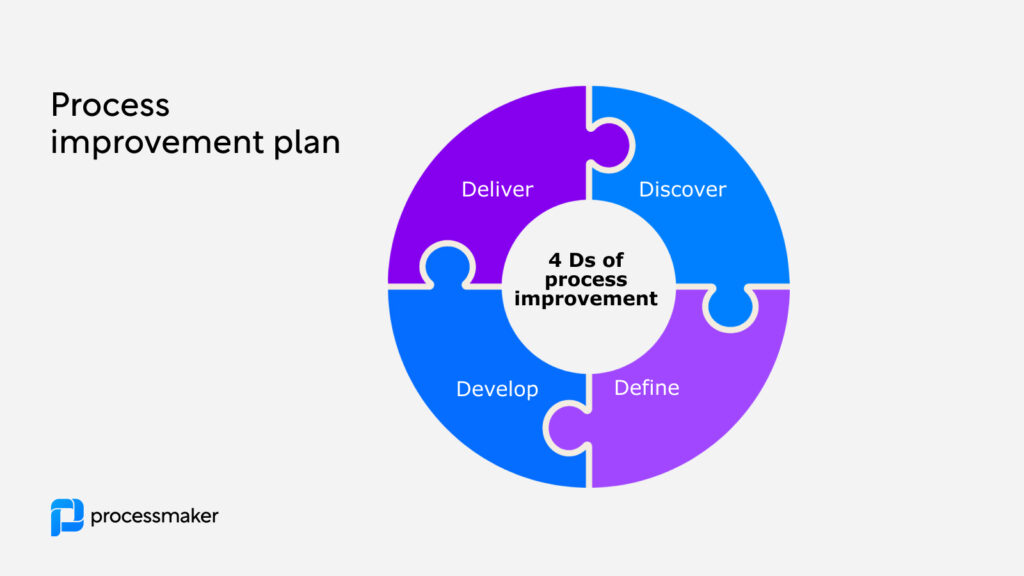

With the right ingredients in place, you can execute your process improvement plan through a simple four “D” framework:

- Discover

- Define

- Develop

- Deliver

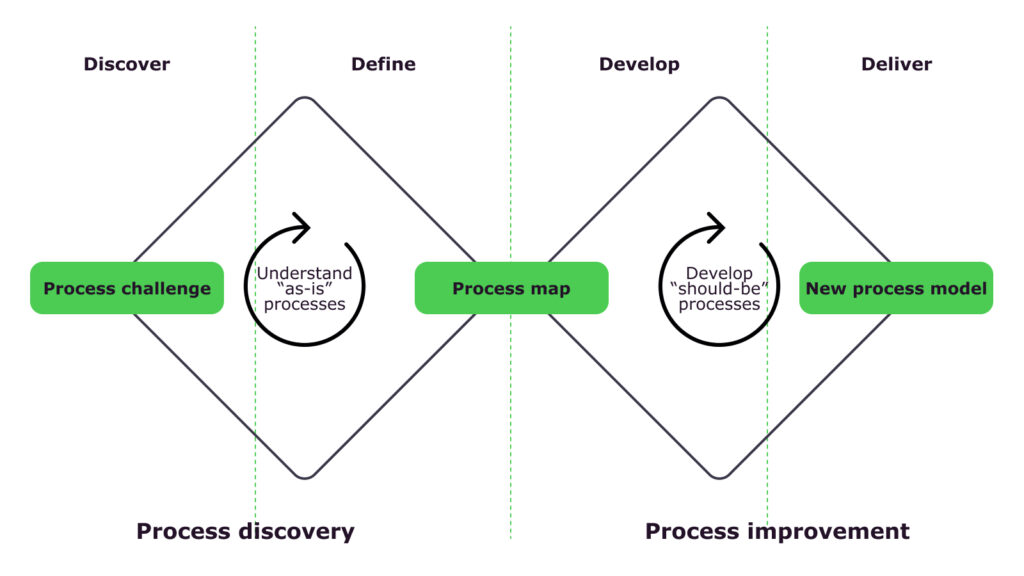

Step 1: Discover as-is through process discovery

Process discovery is the initial phase of creating a process improvement plan. This step involves identifying the existing business processes that need improvement. Some techniques to achieve this include observation, document analysis, interviews, and workshops. The goal is to fully understand the current state of the process and identify the areas for improvement.

Key decision points for process discovery

How you do your process discovery will have a major impact on the amount of insights and value you get out of this key step.

In the past, process discovery has been done through workshops, interviews of key stakeholders, or through time and motion studies observing employees as they work. This proven method is the cornerstone of business process analysis, but it does have limitations supporting process improvement plans. Typically, manual discovery takes time and resources to execute, and if done on a project basis, process discovery doesn’t provide insights for maintaining a continuous improvement plan.

Today, automated process discovery solutions such as process mining and task mining make the process discovery step much more detailed, efficient, and scientific. Additionally, many tools offering automated process discovery functionality will provide improvement opportunities, conformance checking, and process simulation.

Step 2: Define should-be through process mapping

After discovering the processes, the next step is process mapping. This involves creating visual representations of the processes identified in the discovery phase. Process maps can help visualize the sequence of events, identify bottlenecks, and uncover inefficiencies that may not be apparent at first glance.

Key elements of process mapping

Process mapping is an integral part of process improvement and can be done in several ways. The simplest form is a basic flowchart, which represents a process linearly using different shapes for tasks, decisions, and the start/end points.

More complex processes may use a swimlane flowchart, where different lanes represent different stakeholders or departments, effectively visualizing not just the tasks but also who is responsible for them.

Value stream maps are particularly useful for manufacturing processes; they map not only the process steps but also the flow of materials and information, highlighting where value is added.

Business Process Model and Notation (BPMN) is a standardized method for multi-tiered process mapping, providing a detailed visualization that includes the sequence, messages, events, and even the specific type of tasks.

Finally, Data Flow Diagrams (DFDs) focus on how data moves through a system, showing where it originates, where it goes, and how it’s altered. By selecting the most suitable method, businesses can create a process map that provides a clear, visual understanding of their operations and paves the way for effective improvements.

Step 3: Develop improvements through collaborative process implementation

Once the process maps are created, the next step is to plan and execute process improvement initiatives within the organization. This involves making the necessary changes identified during the mapping phase. It’s crucial to communicate these changes effectively to all stakeholders and provide the necessary training to ensure a smooth transition.

Effective techniques for process improvement methodologies

To get meaningful impact, process improvement requires a comprehensive, strategic approach. Here are several key aspects that can contribute to successful implementation.

Engaging stakeholders: To ensure a smooth transition, it’s essential to engage all stakeholders early in the process. This includes not only those who will be directly involved in the changes but also anyone affected by them. Involving stakeholders helps garner support, encourage cooperation, and identify potential issues early on.

Effective communication: Clear and consistent communication is vital throughout the implementation process. Everyone involved should understand what changes are being made, why they’re important, and what their role is in the process. Regular updates should be provided to keep everyone informed of progress and any changes to the plan.

Providing training: If the process changes require new skills or knowledge, providing training is crucial. This could involve one-on-one training, workshops, or online resources, depending on the complexity of the changes and the learning styles of the employees.

Step 4: Deliver results through process standardization

The final step in creating a process improvement plan is process standardization. This ensures consistency and continuity in the way processes are carried out across the organization. Standardization also aids in reducing variations and errors, thus improving overall operational efficiency.

Process standardization, in simple terms, refers to the practice of establishing uniform procedures for different business operations. This ensures that tasks are performed consistently, regardless of who performs them or when they are carried out.

Why is standardization vital for processes?

By establishing clear, repeatable processes, companies can eliminate variation, improve efficiency, and drive predictability in outcomes.

- Consistency in Output. Process standardization ensures that outputs are consistent, no matter who is doing the work. This leads to improved product or service quality and customer satisfaction.

- Reduced Errors and Increased Quality. By reducing variability in processes, standardization helps decrease errors, improving the quality of outputs.

- Increased Efficiency. Standardized processes remove unnecessary steps, reduce redundancy, and streamline workflows, leading to increased operational efficiency.

- Enhanced Compliance. Standardization simplifies compliance with regulatory requirements, as processes are clearly defined and easily auditable.

Implementing continuous process improvement

Implementing continuous process improvement requires a structured approach. Here are some steps to follow:

- Establish a process improvement team: Assemble a team of employees from various departments to lead the improvement effort. This team should include individuals with diverse skills and perspectives.

- Define the scope: Identify the specific process or area to be improved. Clearly define the boundaries and objectives of the improvement initiative.

- Gather data: Collect data on the current process, including metrics and customer feedback. This data will serve as the baseline for measuring improvements.

- Analyze the data: Use tools such as process mapping and root cause analysis to identify areas for improvement. Look for patterns, bottlenecks, and inefficiencies.

- Develop a plan: Create a plan for implementing changes, including timelines and resources required. Ensure that the plan is realistic and achievable.

- Implement changes: Put the plan into action, and monitor progress. Communicate the changes effectively to all stakeholders and provide necessary training.

- Evaluate and refine: Continuously evaluate the effectiveness of the changes and refine the process as needed. Use performance metrics to track progress and make adjustments.

By following these steps, organizations can create a culture of continuous process improvement that drives long-term success.

Using technology to support process improvement

Technology can play a significant role in supporting process improvement efforts. Here are some tools to consider:

- Project management software: Helps to track progress and manage tasks. Tools like Asana, Trello, and Microsoft Project can streamline project management and ensure that improvement initiatives stay on track.

- Process mapping software: Enables the creation of visual process maps to identify inefficiencies. Software like ProcessMaker, Lucidchart, and Microsoft Visio can help visualize processes and uncover areas for improvement.

- Business process management (BPM) software: Automates and streamlines processes. BPM tools like ProcessMaker BPM can help manage and optimize business processes.

- Data analytics software: Provides insights into process performance and customer feedback. Tools like Tableau, Power BI, and Google Analytics can help analyze data and identify trends.

- Collaboration tools: Facilitates communication and teamwork among employees. Platforms like Slack, Microsoft Teams, and Zoom can enhance collaboration and ensure that everyone is aligned.

When selecting technology, consider the specific needs of your organization and the level of integration required with existing systems. The right tools can significantly enhance your process improvement efforts and drive better results.

Best practices to optimize your process improvement plan

It’s important to remember that process improvement is an ongoing activity. It’s crucial to consistently monitor and analyze the improved processes for potential enhancements. Involving team members in the process and establishing a culture of continuous improvement are other key strategies to optimize your process improvement plan.

Use the right process improvement KPIs

When developing a process improvement plan, it’s important to use measurable goals and targets that define more efficient operations.

10 key performance indicators (KPIs) that can be used for measuring the success of process improvement:

- Cycle time: This measures the total time from the beginning to the end of your process. By reducing this time, you can improve productivity.

- Cost per transaction: This KPI helps you determine the cost-effectiveness of a process by measuring how much each transaction costs in resources.

- Process efficiency: This KPI measures the ratio of output to input in your processes. A high efficiency indicates that a process is producing a high output with minimal waste.

- Error rate: Monitoring the number of errors or defects can help you evaluate the quality of a process and its improvement over time.

- Customer satisfaction: By conducting surveys or collecting feedback, you can measure how satisfied customers are with a particular process.

- Employee productivity: This KPI measures the amount of work each employee is able to complete. Improvements in this area could indicate successful process changes.

- Compliance rate: If your processes need to comply with specific regulations or standards, this KPI can track your success rate in meeting those requirements.

- First-time-right rate: This KPI assesses the effectiveness of a process by measuring how often tasks are completed correctly the first time.

- On-time completion rate: This measures how often processes are completed within the expected timeframe.

- Waste reduction: In a manufacturing or production context, this KPI can be used to measure the amount of waste produced in a process and how this decreases over time with improvements.

Conclusion

Creating a process improvement plan may seem like a daunting task, but with the right approach and techniques, it can significantly boost the efficiency and productivity of your business. Remember, the process improvement plan is a strategic tool that aids in continuous innovation and competitiveness in today’s dynamic market. From process discovery, mapping, and implementation, to standardization, each step plays a vital role in refining and enhancing your business processes.