Process mapping is a methodology widely used by professionals working on analytical process improvement. The first step is to conceptualize the inputs, interactions, results, and individuals involved in the operations and decision-making of an organization, as well as to identify process bottlenecks, pattern breaks, and progress options by recording and observation on realistic procedures.

Nevertheless, the usefulness of process mapping relies on the personal understanding of the user. For instance, in one project, process mapping may be used to detail core processes and define non-value added operations to expedite progress. Yet, in another scenario, professionals could fail at understanding the underlying issues they were trying to address.

You need to first learn why process maps are useful for recognizing what could go badly.

In fact, a process map can show how a particular task is performed. Similar to a flow chart, except that it permits several uncertainties to take place. A staff member may, for example, hit step 5 and may need to make a choice between steps 5.1 or 5.2, based on the results of the step. This is one of the main benefits of this method of mapping.

Since you now know why process maps can be so relevant to your company, you’re ready to dive deeper into this popular method of mapping mistakes that individuals generally make when they generate them.

Process Mapping Gone Wrong: 7 Common Workflow Mistakes

1. Bad information

When workflows are neglected, antiquated material is used and standards become vague. There is no doubt that a poorly communicated process will implode. With unsustainable practices, no company can survive and a lack of communication is simply this: Dysfunctional.

Things can be turned around properly through accurate document generation and workflow automation. Team members can then get updates and preferred alerts in real-time. Among the many advantages of automation is that individuals are only informed of their own assignments, and they are not flooded with irrelevant information –keeping communication channels open and concentrated.

Document generation only enhances the procedure by retrieving the most recent data for associated use. Both programs work in conjunction to help stop a lack of communication and to encourage feasible procedures.

2. Paying too much attention to what not to do

Don’t focus too much on telling employees what not to do. Instructions that are focused on the don’ts and won’ts usually end up highly confusing to people. For the end recipient, constructive language is much simpler and less likely to be misinterpreted. Although alerts may be needed for a job, specifically if a work that is poorly managed is dangerous, the language and instructions should be generally positive.

Many of us have already seen this scenario occur: A company buys a fantastic new technological solution and then enacts the new software before even examining the organization’s key processes and individuals who are associated with it. The outcome? Most of the time, the project cannot deliver on its promises–it eclipses the spending limit, takes much longer than expected to manage, or does not meet the company’s initial objectives.

Even when things do turn out positively. the new solution just starts to feel like the technology it was intended to replace. The staff starts to wonder why everyone had to go through such mind-boggling processes that just don’t seem as efficient as the old system. What really happened though? In most instances, the business failed to review and improve its underlying processes.

3. Focusing on every little detail before looking at the context

People are usually anxious to get started on a new project — especially one with objectives around overall process improvement. SMEs stand

ready to convey their processes and how they are performed. Your company may even have a set of mapped out processes from a previous initiative.

With this in mind, the planning can quickly revert to these types of details without any attention given to how processes relate to each other and the context for each. So then, in terms of context, all associated team members must come from the same understanding of the overall context. If not, the project can easily come to a halt.

4. Outdated process maps

In terms of process map systems, they should always be updated to the most recent version. What works for today may not be as efficient in the future. Today’s legal structures and regulations are apt to change in the future. Plus, the way a job is handled may vary depending on the tool used.

Why aren’t process maps updated more often? Probably because there isn’t a designated individual with the task of keeping them updated. Or, resources weren’t properly allocated to ensure that the process maps are as recent as possible.

5. The process maps become too complicated for anyone to comprehend

No one knows who should be in charge of keeping the maps updated. What’s the answer? Make sure the process maps are a living tool that is updated. Designate a person to be responsible for managing the process maps. In addition, send out reminders to review the maps periodically. Make the maps as clear as possible.

6. No one knows what role to play

In terms of process maps, and team members, someone has to take a leadership role. Even if there are cross-team responsibilities, someone has to take charge and lead everyone else to the desired results. Without experience, even analysts can fail to regard the significance of a leadership role in helming the tasks at hand.

In conclusion

Workflows are prevalent in business, yet we continue to experience the same inconsistencies. If these frequent errors are not resolved, the organization may waste a lot of time, work quality, and productivity.

Time is also wasted due to poor information sharing and insufficient preparation. If new data can’t be added, then overall workflow quality starts to suffer. And if the end isn’t in sight, morale starts to decrease.

These types of errors take time, money, and concentration to address them efficiently. Nevertheless, organizations that understand how to address common workflow mistakes will enjoy better processes and improved results. Even if some of these mistakes can be challenging to resolve, the ability to fix the errors offers consistent rewards.

Schedule a demo today

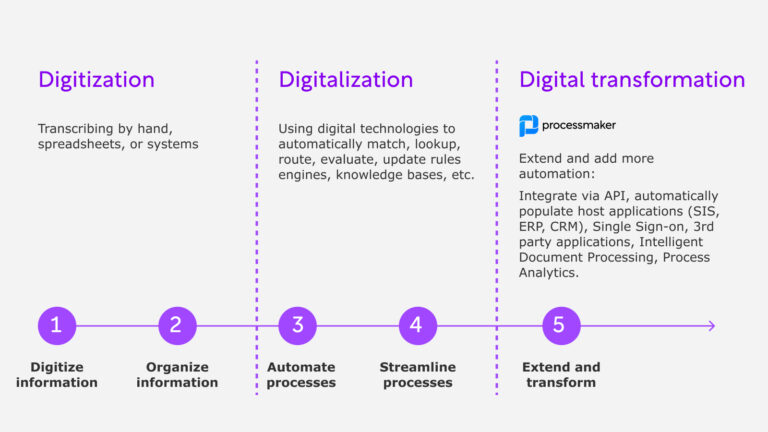

ProcessMaker specializes in improving the business processes of some of the world’s largest banks. Hundreds of commercial customers, including many Fortune 100 companies, rely on ProcessMaker to digitally transform their core business processes enabling faster decision making, improved compliance, and better performance. Schedule your free demo today to realize the potential of ProcessMaker.