In today’s volatile and uncertain market conditions, businesses around the world face unprecedented pressure to increase operational efficiency. At the same time, procurement organizations face challenges digitizing complex source-to-pay processes, leaving little room for error. Faced with such complex challenges, procurement leaders are increasingly turning to process mining software to transform the performance of their procurement organizations.

In this article, we go through the opportunity in process mining with definitions, examples, and best practices every CPO and procurement leader needs to know.

What is process mining?

Process mining is a technique for extracting data from information system event logs in order to locate, monitor, and enhance real-world business processes. Process mining is a technique that can be used to locate process bottlenecks or inefficiencies, provide insight into how processes are carried out, and eventually enhance business process performance.

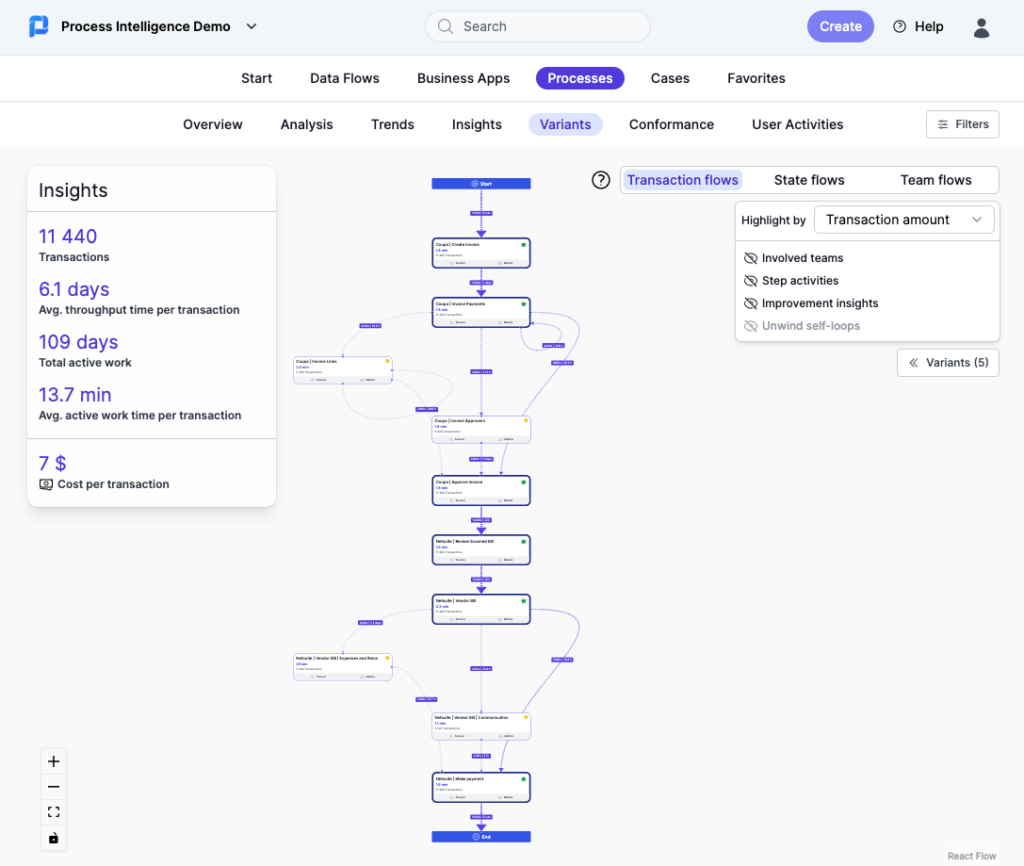

Example of procurement process analysis – ProcessMaker Process Intelligence

Process mining can be considered an automatic and advanced tool for business process analysis. In this way, procurement organizations benefit from five key areas of process analysis and optimization:

- Process discovery – from identifying the “as-is” true state of your procure-to-pay or source-to-pay processes.

- Process mapping – defining and communicating the desired state of processes across your organization and with key stakeholders.

- Process monitoring – keeping track of conformance to your agreed processes and approval steps across teams or the organization.

- Process reengineering – the systematic re-design of key processes to increase efficiency.

- Digital transformation – procurement processes are often manual and time-consuming, process mining can be used to accelerate digitalization or digital transformation.

How process mining works

Process mining operates by collecting data from event logs, which are essentially digital footprints of the activities performed within a process. These logs are typically generated by enterprise systems such as ERP or procurement software. Once collected, the data is analyzed using specialized process mining tools and techniques.

The process begins with process discovery, where the actual process flow is reconstructed from the event log data. This provides a visual representation of the process, highlighting the sequence of activities and their interdependencies. Next, conformance checking compares the discovered process with the intended process model to identify deviations and non-compliance issues. Finally, process enhancement involves analyzing the process to identify areas for improvement and opportunities for automation.

By utilizing these techniques, procurement organizations can gain a comprehensive understanding of their procurement processes, uncover inefficiencies, and make data-driven decisions to optimize performance.

Typical process mining use cases for procurement

Procurement processes can be among the most complex and manual in business operations. They typically involve many departments and involve many steps of approvals across various stakeholders. Procurement processes can involve large amounts of transactions where even proven experts are prone to human error.

Each procurement organization will have specific challenges and areas for improvement. Overall, the typical use cases for process mining in procurement include:

- Identify bottlenecks with end-to-end process visibility. Typically 80% of procurement process challenges come from 20% of cases. The problem is that it’s difficult to fix issues without measuring them first.

- Harmonize processes among teams and business units. Once you have mapped out the true state of your procurement processes among different teams you can benchmark, harmonize, and align processes based on desired best practices.

- Reduce lead time and need for core processes. Reduce the need for manual work within purchase orders, for example, reducing the free-text requisitions or approvals needed.

- Improve the level of digitalization and automation. Reduce the amount of manual review and approval time, for example, by increasing the touchless PO rates or automated approvals.

- Maximize working capital. Process mining can be used to measure and harmonize payment terms, ensuring payments are made at the optimal due dates, or through negotiated better payment terms.

Example of a procure-to-pay process

Consider a procurement organization looking to optimize its procure-to-pay process. By applying process mining, the organization can collect data from event logs to analyze the entire process from purchase requisition to payment. This analysis can reveal bottlenecks, such as delays in approval or payment processing, and identify inefficiencies that need to be addressed.

For instance, the analysis might show that a significant amount of time is spent on manual approval steps. By automating these steps, the organization can reduce lead times and improve efficiency. Additionally, integrating with suppliers’ systems can streamline communication and further enhance the procurement process. Through these improvements, the organization can reduce costs, strengthen supplier relationships, and boost overall procurement performance.

Key questions process mining can answer in P2P

Once you apply a process analysis mindset to procure-to-pay you can start answering key questions impacting your organization’s performance. Some key questions can include:

- How long does it take for procurement requests to be processed?

- How accurately are POs processed across teams or business units?

- What are the process steps for increasing the lead time of purchases?

- What are the areas where more errors or rework are needed in purchases?

- How widely is your organization complying with the agreed P2P model?

- How much of your spending is managed by procurement?

The business case for process mining in procurement

You can adopt a five-step process in developing a credible business case for process mining in procurement.

- Determine the greatest improvement areas. Analyze data and conduct research to find areas where the purchasing process needs to be improved and where unnecessary steps can be eliminated.

- Calculate cost savings. Describe the possible savings that can be achieved by doing away with manual processes, cutting expenses, and streamlining operations.

- Explore other measurable benefits. Explore other performance metrics that can be impacted, for example, reduced lead time, removal of rework, rate of on-time payment, reduced number of errors, reduced maverick spending, etc.

- Estimate the total cost of ownership and possible ROI. To create a business case for process mining, determine the total cost of implementing possible return on investment (ROI) from process changes, including cost savings and other measurable benefits.

- Make your argument realistically and for the long term. To obtain approval, provide leadership and key stakeholders with the business case for process mining in concrete benefits and realistic timeframes.

Process mining best practices for procurement organizations

With an effective business case, you’re off to a good start. Here are a few best practices to ensure your process mining initiatives have a long-term impact.

- Start with a clear goal and strategy. Before embarking on a process mining initiative, define a strategy and ensure that process mining project goals are aligned with the overall business objectives.

- Define clear success metrics. Establish clear and measurable ways to evaluate success in metrics that have concrete business benefits.

- Identify best-fit software. There are more than 30 process intelligence software solutions in the market – including process mining, task mining and advanced hybrid options. Explore and identify tools that suit your needs through a proof-of-concept or process intelligence RFP.

- Include relevant stakeholders. Identify and build the winning team to take on a process mining implementation within and outside of the procurement organization.

- Develop a robust training program. Remember that process mining is not a silver bullet, it will require learning and training of key stakeholders.

- Aim for long-term gains. Process mining can bring both short-term and long-term benefits, but it’s rarely a one-time fix. Build a roadmap of initiatives that build up incremental operational improvements.

Example of how process mining can be used in the procurement process

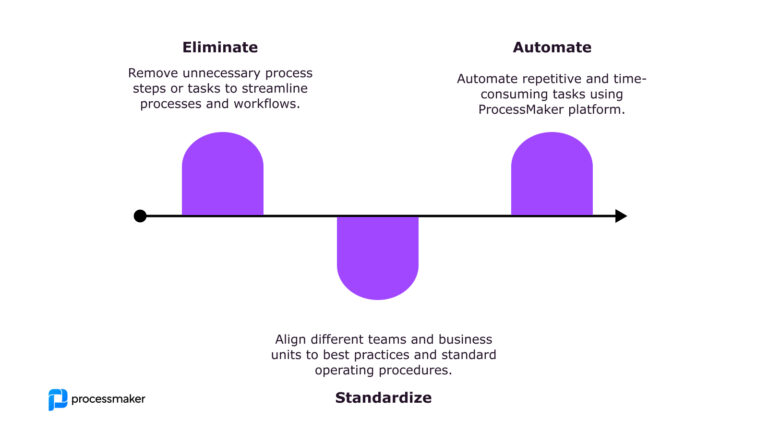

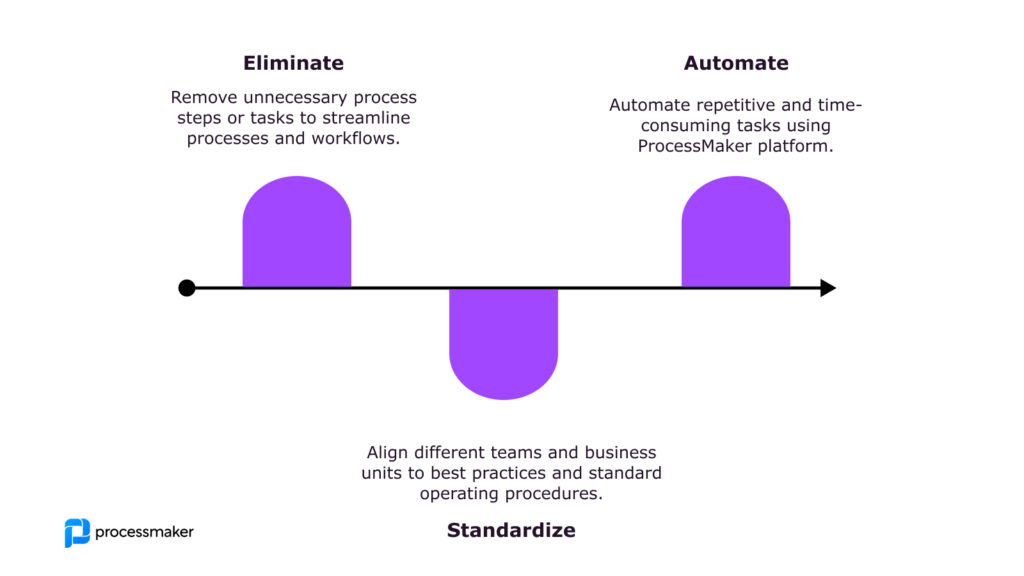

Process mining is an enabler for process improvement. For procurement teams, you can see three types of optimizations that can result from process mining and analysis using the ESA framework:

Procurement process mining can enhance efficiency and effectiveness by eliminating unnecessary approval steps, standardizing processes across teams, and automating repetitive tasks through robotic process automation (RPA).

Improving procurement processes based on the ESA framework by ProcessMaker

Eliminate – the removal of procurement approval or control steps to streamline key workflows.

Standardize – aligning different teams to the agreed P2P model, ensuring risk control and reducing maverick buying.

Automate – utilizing Business Process Automation (BPA) software to completely remove human intervention from repetitive procurement tasks.

Limitations of process mining for procurement

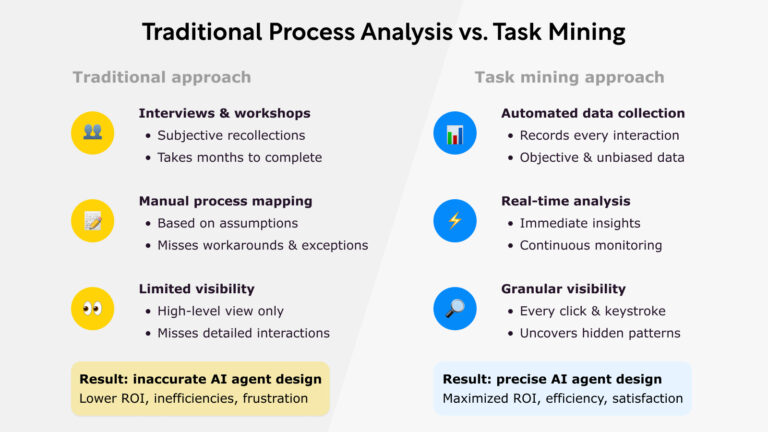

- Can’t assess the full cost of work. A typical procurement team needs access to over 25 different business apps, Excel reports, 3rd party portals and other data systems. Process mining doesn’t give full visibility to the manual effort required in processing.

- Lack of (quality) data. Because process mining techniques are dependent on event log files, they are limited to the data that is available, so it may not be able to uncover all the information about the procurement process happening outside of enterprise resource systems (ERPs)

- Total cost of implementation. Process mining can be costly to set up, as it requires the gathering and storing of data over a period of time from different data source systems – in addition, the maintenance of process mining resources increases the total cost of ownership.

- Automated insights are not flawless. Process mining is not always able to detect process inefficiencies, so it may not be able to identify all potential issues.

- Lack of agility. Process mining solutions can be time-consuming to set up across a procurement organization or many business units.

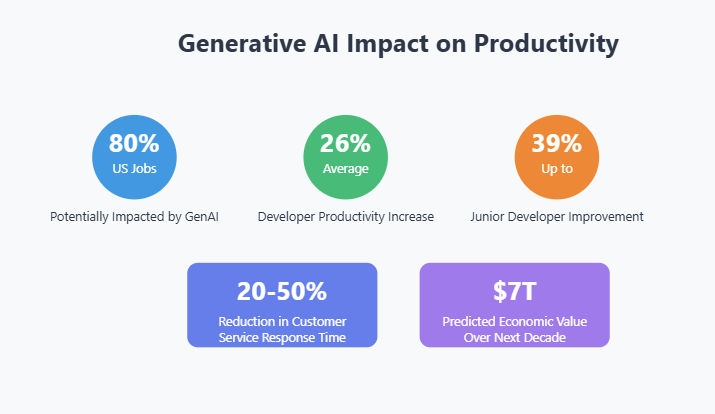

Consider an alternative: hybrid process intelligence

If you’ve already used process mining or are still weighing your options, hybrid process intelligence software might be something to look into. With this new method, you have the task mining software’s level of detail and the process mining software’s breadth of coverage. Additionally, it can be implemented 10 times quicker than the well-known process mining solution.