Process excellence is a commonly used term within business process management. It can mean different things to different people. In this article, we look at different perspectives and summarize what enterprise leaders need to know about business process excellence.

What is Process Excellence?

Process excellence is the practice of continually improving the efficiency, effectiveness, and quality of business processes and operations through an operational excellence framework. It is a combination of process improvement, process design, and process management techniques that strive to optimize organizational performance. Process excellence enables organizations to deliver better results and drive growth.

Why is process excellence important?

Process excellence is an ongoing effort to improve the way businesses operate and create value for customers, employees, and stakeholders. Organizations use it to identify opportunities for improvement and create innovative solutions. Process excellence focuses on a range of different process-based activities, such as process mapping, process automation, and process reengineering. Process excellence is a powerful tool for organizations to improve the quality, speed, and cost of their operations. It helps organizations identify process weaknesses and design better solutions.

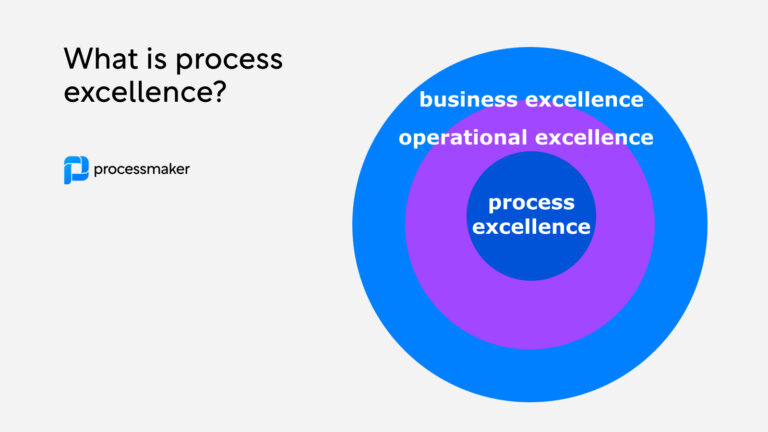

Process excellence vs Operational Excellence vs Business excellence

Process excellence, operational excellence, and business excellence are related concepts that focus on improving organizational performance.

- Process excellence (PEX) is the practice of continually improving the efficiency, effectiveness, and quality of business processes and operations.

- Operational excellence (OpEX) focuses on streamlining and optimizing daily activities and operations.

- Business excellence (BEX) focuses on creating customer value and achieving long-term organizational objectives. All three approaches are essential to achieving organizational excellence and creating a competitive advantage.

How process excellence relates to operational excellence and business excellence

Top 10 process excellence tools and methodologies

Process excellence is neither an art nor a science. In fact, it’s a combination of both. You can leverage a toolkit of different methodologies or systems to achieve process excellence in the workplace but there is no one standard way to achieve results. The top 10 tools to consider include:

- Six Sigma: Six Sigma is a data-driven methodology focused on reducing process variability and defects. It utilizes statistical analysis to identify the root causes of problems and implement improvements. The methodology follows two project management frameworks: DMAIC (Define, Measure, Analyze, Improve, Control) for existing processes and DMADV (Define, Measure, Analyze, Design, Verify) for new business processes.

- Lean: Lean methodology aims to maximize customer value while minimizing waste. It seeks to create more value with fewer resources by eliminating non-value-adding activities or processes. Lean principles include continuous improvement, respect for people, standardized work, pull-based production, and just-in-time production.

- Kaizen: Kaizen is a Japanese term that means continuous improvement. It involves small, incremental changes aimed at optimizing processes and eliminating waste. Kaizen encourages employee involvement and teamwork, fostering a culture of continuous learning and improvement.

- Total Quality Management (TQM): TQM is a management approach that aims to achieve long-term success through customer satisfaction. It focuses on continuous improvement, employee empowerment, and efficient processes. Key TQM principles include a customer-centric approach, management commitment, continuous improvement, and employee involvement.

- Business Process Reengineering (BPR): BPR involves a radical redesign of an organization’s processes to achieve significant improvements in performance, such as cost reduction, speed, and quality. It requires a thorough analysis of existing processes and the development of new, more efficient ones.

- Value Stream Mapping (VSM): VSM is a Lean tool used to visually represent the flow of materials and information within a process. It helps identify bottlenecks, waste, and opportunities for improvement. VSM enables organizations to optimize their processes by focusing on value-adding activities and minimizing non-value-adding ones.

- 5S: 5S is a workplace organization methodology that originated in Japan. It consists of five steps: Sort, Set in order, Shine, Standardize, and Sustain. The goal is to create a clean, organized, and efficient work environment that fosters productivity and safety.

- PDCA (Plan-Do-Check-Act): PDCA is a continuous improvement cycle used to solve problems and improve processes. It involves planning the change (Plan), implementing the change (Do), reviewing the results (Check), and making necessary adjustments (Act). The cycle is then repeated to ensure continuous improvement.

- Balanced Scorecard (BSC): BSC is a strategic management tool that translates an organization’s vision and strategy into a set of performance measures. It provides a comprehensive view of an organization’s performance by considering four perspectives: financial, customer, internal processes, and learning and growth.

- Gemba Walk: Gemba Walk is a Lean management practice that involves managers and leaders visiting the workplace (gemba) to observe processes, engage with employees, and identify areas for improvement. It promotes continuous improvement, employee engagement, and a better understanding of the work environment.

Process excellence in the workplace

Process excellence can be seen as a key part of an organization’s overall performance management system. Increasingly enterprise businesses are recognizing business process excellence as an important element of organizational success. It helps organizations align their processes with their strategic objectives, improve customer service, and increase efficiency.

Key steps of a process excellence framework

While process excellence is a broad term that can mean different things to different people, there are eight key activity stages or steps that fall within its framework:

- Process mapping: Identifying the steps, resources, and objectives of a process.

- Process improvement: Identifying opportunities to reduce costs and improve efficiency.

- Process design: Creating ideal ‘happy path’ processes to meet customer needs and organizational goals.

- Process monitoring: Monitoring processes to ensure they are meeting objectives and delivering quality results.

- Process optimization: Evaluating and improving processes to maximize efficiency and effectiveness.

- Process automation: Using software or other technology to automate manual tasks.

- Process standardization: Establishing consistent processes across the organization.

- Process governance: Establishing standards, policies, and guidelines for process management.

FAQs:

1. How do you achieve process excellence?

Achieving process excellence involves identifying, analyzing, and optimizing an organization’s processes to improve efficiency, quality, and customer satisfaction. This can be done by implementing various methodologies, such as Six Sigma, Lean, and Kaizen, among others. Therefore, to achieve business process excellence, organizations should establish a culture of continuous improvement, engage employees at all levels, use data-driven decision-making, and regularly review and refine their processes.

2. Why is process excellence important?

Process excellence is important because it helps organizations reduce costs, minimize waste, improve efficiency, and deliver high-quality products and services. By achieving process excellence, organizations can enhance customer satisfaction, gain a competitive advantage, and ensure long-term success. Furthermore, business process excellence contributes to a better work environment, increased employee engagement, and a culture of continuous learning and improvement.

3. What are the stages of process excellence?

There is no universally agreed-upon set of stages of process excellence. However, a general framework could include the following four stages:

- Assessment: Evaluate the current state of an organization’s processes, identify areas for improvement, and set goals.

- Implementation: Apply process excellence methodologies and tools, such as Lean or Six Sigma, to optimize business processes, eliminate waste, and improve efficiency.

- Monitoring: Continuously track the performance of optimized processes using key performance indicators (KPIs) to ensure improvements are sustained and desired results are achieved.

- Continuous improvement: Regularly review and refine processes based on the monitoring stage’s findings, fostering a culture of ongoing learning and improvement.

4. What does a process excellence team do?

A process excellence team or department is responsible for facilitating and promoting the adoption of process excellence methodologies and tools throughout the organization. Their tasks may include providing training and resources to employees, leading process improvement projects, analyzing and monitoring process performance, and driving a culture of continuous improvement. Additionally, the department may work closely with other functional areas to identify opportunities for improvement, collaborate on cross-functional initiatives, and ensure that process excellence goals are aligned with the organization’s overall strategy.