The Problem

A global manufacturing company faced a significant process challenge with its purchase orders (PO). Previous attempts by multiple vendors had failed to solve the visibility problem of the end-to-end PO process. ProcessMaker's process intelligence platform was able to successfully tackle this ultimate challenge and lead the game thanks to its agility, speed of execution, and innovative approach.

The case company is a global manufacturing enterprise that operates in almost 100 countries and serves customers with solutions mainly in the infrastructure, utility, and industry sectors. Their primary objective was to streamline the PO creation process which could potentially lead to higher process efficiency and cost savings.

The manufacturer’s main challenge was to get full visibility over the PO creation process across different regions and geographies that use different versions of SAP. Inaccuracies with supplier master data were causing issues with process execution and creating a lot of variances, but they couldn’t quantify it or find the root causes. Achieving a holistic view of the PO creation process would identify bottlenecks in the current process and discover improvement opportunities.

The manufacturer knew the problem very well, had well-defined success criteria, and knew exactly what it was looking for in a vendor, making the challenge clear but complex.

Additional challenges included automatically identifying and visualizing the different paths taken during the PO creation process, comparing and benchmarking between different locations and buyers, and finding the shadow tools used in the PO creation process. A better way to capture and analyze process data at scale was needed.

The Solution

ProcessMaker Process Intelligence quickly captured and analyzed all PO data. Process Intelligence eliminated the need to access system event logs that are hard to get or sometimes even non-existent. Instead, locally installed agents collected the process data from the user interfaces based on the pre-defined rules specified by the customers. To ensure the privacy and security of individuals’ data, the data was collected at the team level.

From the collected data, Process Intelligence generated the enriched event logs that are cleaned locally and are then sent to the cloud, where they were analyzed to transform the collected data into operational insights. This analysis includes process mining, task mining, and other algorithms and calculations that transform the collected data into operational insights. All of the above steps are done automatically and don't require any manual effort.

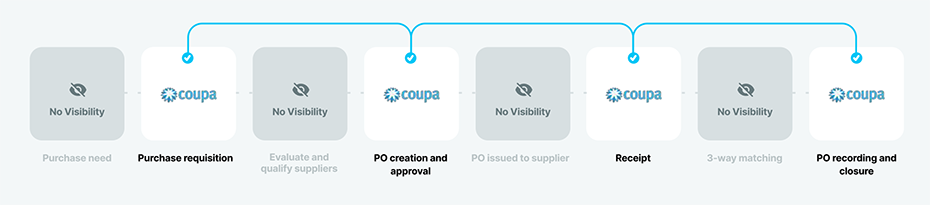

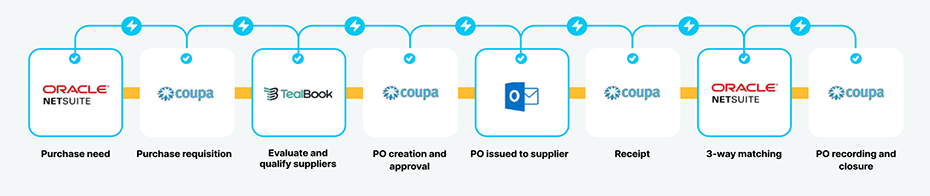

Process visibility with traditional methods

Process visibility with traditional methods

The Value Created

Process Intelligence was able to map the end-to-end PO creation process and exceed the following success criteria:

- Visualizing different process paths within the PO creation process.

- Identifying the throughput time of the process paths and the concrete steps that make up those paths.

- Discovering the additional apps and documents that are involved in the PO creation process and identifying how and when they are used.

- Finding automation opportunities.

- Analyzing the data and identifying the patterns regarding the same materials or suppliers.

- Capturing manual field changes in SAP and their impact on the PO process.

- Recognizing the common path and how often it was followed.

This case demonstrates how Process Intelligence overcame the PO creation challenges through its agile and innovative approach. By providing comprehensive visibility, analysis, and automation opportunities, ProcessMaker Process Intelligence led to a successful partnership and a much more efficient PO creation process.